Turn-Key, Fully Automatic Heat & Fire Detection and Suppression Systems Designed to Protect Recycling Plants and Waste Management Facilities

In recent years, despite the rapid leap in technology of heat detection, fire detection, and fire extinguishing and suppression systems, the recycling and waste management industries face significant challenges in finding a turn-key, off-the-shelf, fully automatic fire detection and suppression system that addresses their specific needs.

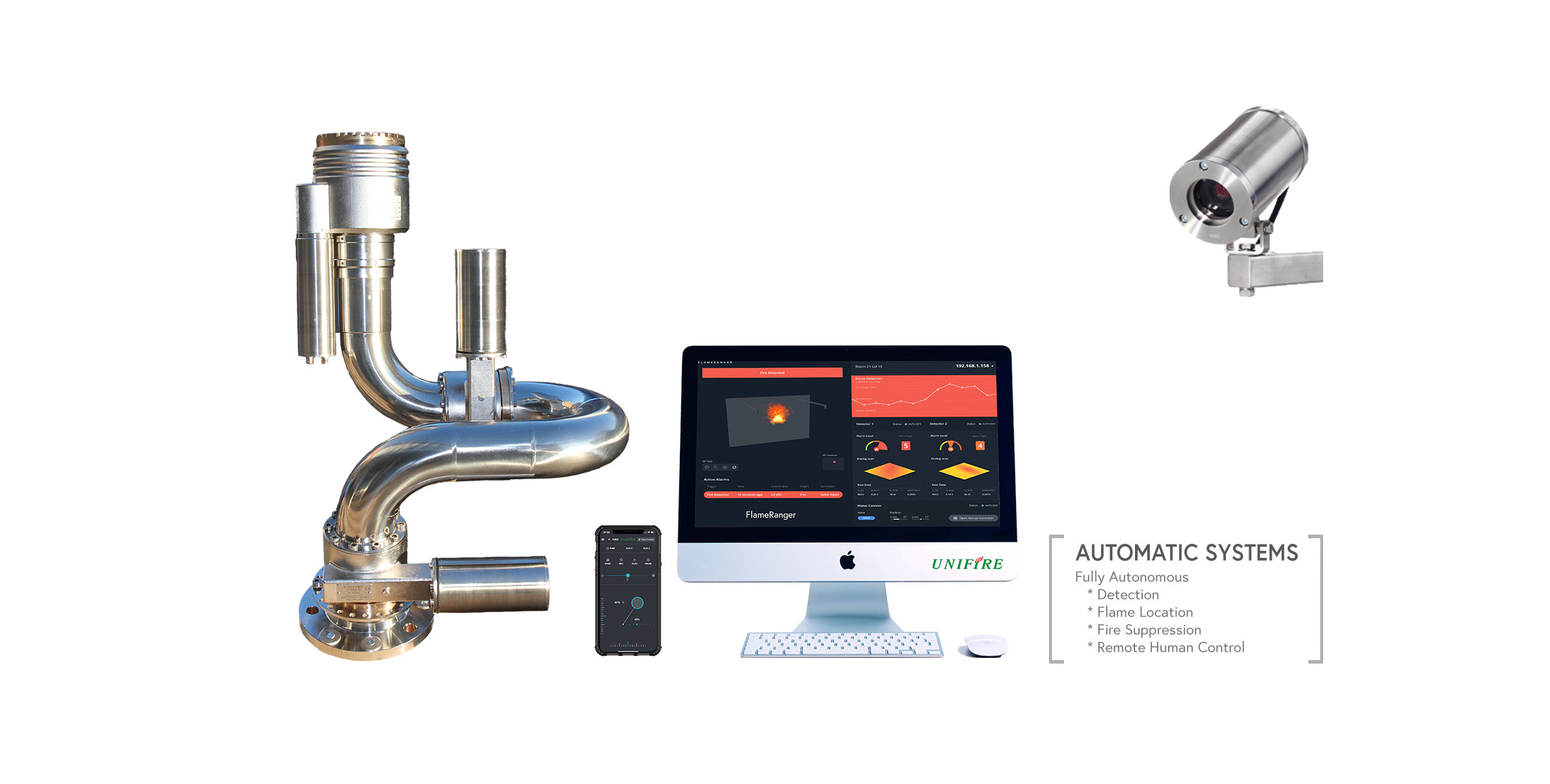

Unifire AB of Sweden has addressed this need and offers off-the-shelf complete systems, which rapidly detect flames and/or heat buildups and automatically suppress the fire or heat source with a high volume of water or foam, directly at the source. Such automatic fire fighting systems are commonly known as “automatic fire monitors” or “autonomous fire suppression” robotic nozzles.

Among others, the recycling and waste to energy plants face a high risk of fire regularly and rapidly breaking out in their facilities. These industries require a fire fighting system that is:

- Fully Automatic;

- Highly Immune To False Alarms;

- Rapidly Detects Heat Build-Ups And Flames;

- Rapidly Suppresses The Fire Or Heat;

- Delivers The Water Or Foam Directly To The Source Of The Heat Or Fire (And Does Not Generally Spread Water Elsewhere); And

- Minimizes The Total Volume Of Water Or Foam Used, So As To Reduce Potentially Toxic Run-Off.

Many other industries and applications can substantially benefit from Unifire’s automatic fire monitors as well. They include, among others:

- Aircraft Hangars

- Tank farms

- Large Volume Spaces (LVS’s) on Aircraft Carriers and Naval Vessels

- Petroleum loading terminals

- Atriums

- Thermal power plants

- Historical Buildings

- High-Rise Building Exteriors

- Production facilities

- Tunnels

For a number of years now, fire fighting systems integrators have been able to piece together various detection technologies with remote controlled fire fighting monitors or robotic nozzles to provide some level of fully automatic fire protection at recycling and waste management facilities.

There is now available on the market, however, turn-key, fully automatic and autonomous fire detection and suppression systems that can be easily installed.

Unifire offers advanced fully automatic fire detection and suppression systems that combine a wide range of state-of-the-art fire detection technologies with the company’s advanced robotic nozzles (also known in the fire fighting industry as remote controlled monitors). Unifire’s systems can include, among others, the following detection technologies:

- IR Array Flame Detectors,

- IR3 Flame Detectors,

- Thermal Imaging Cameras,

- Video Analytics, and

- Linear Heat Detection Systems (e.g., Fibre Optic Cables).

Unifire’s turn-key solutions provide rapid detection of heat build-ups and/or flames and are able to automatically guide its robotic nozzles (fire fighting monitors) to deliver a high volume of water or foam directly on the source of the fire or heat risk. Importantly, Unifire’s systems also shut off automatically shortly after the flames or heat are no longer detected.

The 4-Step Process of Automatic Fire or Heat Detection & Suppression

| Detection Technology: | PRO’s | CON’s |

| Thermal Imaging Cameras | Rapidly and accurately detect heat buildups, giving early warning of an impending fire risk before any flames are visible. | Susceptible to False Alarms: heat buildups can come from hot machinery and other sources that are not the risk seeking to be prevented, leading to the possibility of false alarms. State-of-the-art thermal imaging cameras minimize this risk through sophisticated algorithms, though the risk cannot be fully eliminated. |

| Tyco FV300 IR Array Flame Detector | 1. Provides real time tracking and aiming with high precision suppression, with human-like control 2. Rapidly detects flames 3. Highly immune to false alarms 4. Provides x, y coordinates of the detected flames, providing 2D size / location information 5. By combining data from 2 detectors, the 3D size/location can be triangulated. 6. By requiring alarm from 2 independent detectors, false alarms are negligible. 7. Can detect and track up to 4 fires simultaneously and queue yet others. | Reacts only to actual visible flames within the view of the detector—it does not react to heat buildup, nor flames hidden from the detector’s view. |

| Other IR & IR3 Flame Detectors | 1. Rapidly detect flames 2. Highly immune to false alarms | 1. React only to actual visible flames within the view of the detector—they do not react to heat buildup, nor flames hidden from the detectors’ view. 2. Flame location not possible, requiring general, full-area or zoned response. This limits effectiveness and increases total water consumption. |

| Video Analytics | 1. Capable of detecting and tracking visible flames, smoke and, in some cases, reflection of flames and/or oil mist 2. Coordinates of the detected risk can be ascertained 3. Highly sensitive 4. Can record video of the event for later analysis 5. Can independently set, adjust, and enable or disable, detection of the various risk categories. | 1. Due to sensitivity and algorithms, video analytics has a relatively high vulnerability to false alarms. Algorithms continue to advance, however, and provide better and better immunity to false alarms. 2. Not recommended for outdoor detection due to vulnerability to false alarms from the sun and sun reflection as well as from wind blowing objects in wave-like patterns |

| Fibre Optics Linear Heat Detectors | 1. One detector can cover a large area (several km of fibre optic cable per detector) 2. Robustness against EMI, humidity, dirt and dust 3. Continuous monitoring of temperature even during fire 4. Low false alarm rate (depending on setting, but generally lower for heat detection) 5. Easy service (one detector unit) | 1. Heat detection is very slow compared with the above detection technologies 2. Poor fire source location accuracy due to convective heat transport from fire to detector Area height and airflow can be crucial 3. Hard to detect smouldering fires (low heat) 4. 3D location not possible. |

- Rapidly Detect a Heat Buildup or Flame

- Determine it’s location

- Automatically aim a high volume of water or foam directly at the fire or heat source until extinguished

- Automatically close the vale to shut off the water or foam

- Remain in standby ready to react again should a fire or heat alarm be detected

Because there are many ways to detect a heat buildup or fire, and depending on the specific risk, some technologies are superior to others, and sometimes a combination of detection technologies is the most effective.

Each detection technology has its advantages and disadvantages when used in a fully automatic fire detection and suppression system. Here is our list of the primary benefits and detriments of each main fire and heat detection technology in automatic systems:

ZoneRanger™: Automatic Fire Fighting Systems Using Thermal Imaging Cameras

Unifire’s systems are tailored to the risk and the customer’s needs. Recycling plants often require thermal imaging cameras in order to detect and react to a heat buildups before visible flames appear.

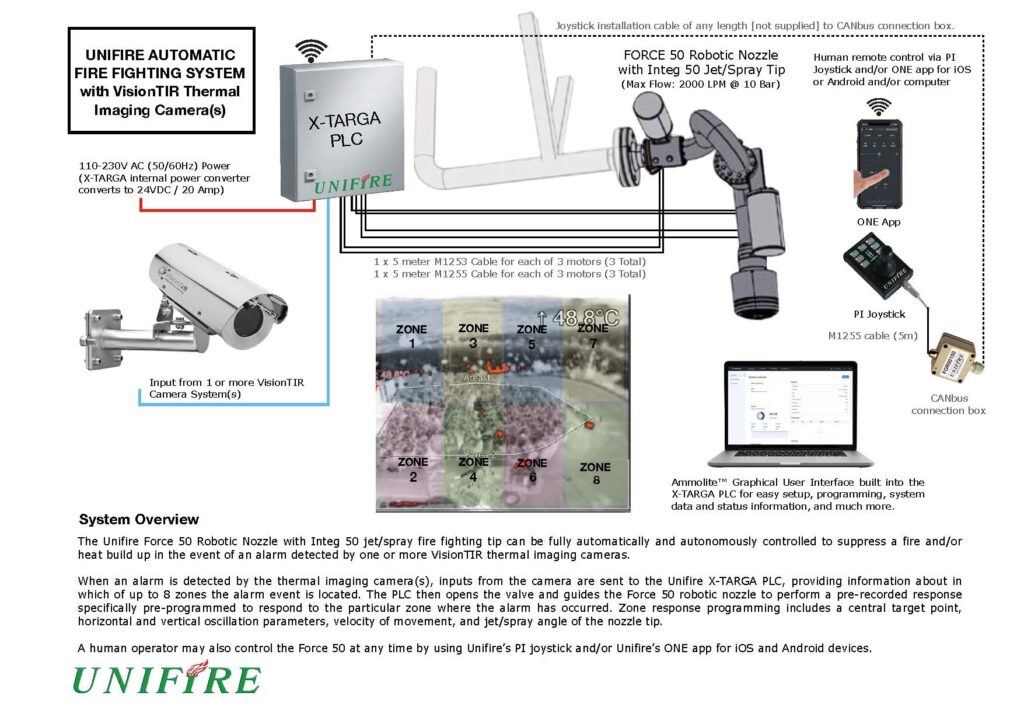

Unifire’s ZoneRanger™ system is a turn-key, fully automatic fire detection and suppression system that utilizes advanced thermal imaging cameras, which are capable of detecting heat buildups in a number of “zones” within its field of view. Alarm parameters can be programmed to the customer’s needs.

Signals from the thermal imaging cameras are processed in Unifire’s advanced TARGA PLC (programmable logic controller), which then automatically guides a Unifire Force 50 or Force 80 robotic nozzle to suppress the zone in which the heat alarm has been detected. The system also automatically opens the valve, and then closes the valve after the alarm is no longer present.

The system is easily set up and commissioned using Unifire’s Ammolite Graphical User Interface. Ammolite allows the installing technician to simply aim the robotic nozzle to the center of each zone, enter in the horizontal and vertical limits for that zone, and program any nozzle spray pattern adjustments desired. These parameters are easy and intuitive to enter, and they only need to be set once, and are then stored in the system’s memory.

In this way, each zone has its own pre-programmed reaction, giving a relatively high-resolution reaction to any heat buildup in view of the thermal imaging camera.

Moreover, two or more thermal imaging cameras can be connected to the TARGA PLC, providing a wide ranger of coverage, with a radius of greater than 60 meters.

FlameRanger™: Automatic Fire Fighting Systems Using Tyco FV300 IR Array Flame Detectors

Among other industries, the waste management and recycling industries regularly experience a rapid breakout of flames.

Unifire’s FlameRanger™ system is best suited to provide the highest level of fire protection for waste to energy and recycling plants. FlameRanger is a unique, turn-key, fully automatic fire detection and suppression system that utilizes flame detectors. Within seconds, it detects fire, locates its exact three-dimensional position, and suppresses it with a high volume of water, directly at its source, then shuts off.

The system works by combining advanced Tyco FlameVision FV300 IR array flame detectors with Unifire’s highly advanced, Force™ high-flow, stainless steel 316L robotic nozzles (a new generation of remote control fire monitors), which feature industrial-robot-type brushless (BLDC) motors, providing extreme accuracy and long life.

When a fire breaks out, it is detected in seconds by the flame detectors, which feed the fire’s coordinates to the system’s advanced electronics, called the TARGA™ PLC. By combining the two dimensional position data from two separate flame detectors, the system’s software is able to triangulate the size and position of the fire in three-dimensions. With this information, the system then aims the robotic nozzle at the fire, and opens a valve to turn on the water and begins extinguishing the fire with a high volume of water or foam, with pinpoint accuracy. According to Unifire, the entire process of detecting a fire, triangulating its 3D size and location, aiming the robotic nozzle, opening the vale and commencing suppression, typically takes only 5-15 seconds.

The system continuously updates the fire’s position 10 times a second, fighting the fire dynamically, in real time, eerily similar to the way a human firefighter would.

As soon as fire is no longer detected, the system signals the valve to close, stopping the flow of water. The system continues detecting for the presence of fire, however, and will recommence suppression should any fire break out again.

By accurately directing a high-volume of water onto the fire so quickly after it has ignited, the system has in full-scale fire tests proven capable of fully extinguishing fires in 20 seconds or less from ignition.

Importantly, the FlameRanger has an extremely low risk of false alarms. Each of the FV300 flame detectors used in the system employs highly advanced algorithms to detect flame, and thus have an extremely low risk of false alarms. Moreover, the FlameRanger system will not react unless two detectors both independently detect a fire, at the same time and at the same location—making the chances of a false alarm negligible, according to Unifire.

In essence, the FlameRanger is very much like having a firefighter on duty 24/7/365—it reacts immediately and fights fire very much like a human firefighter. According to Unifire’s Director of International Sales & Marketing, Roger Barrett James, Esq., “In fact, one of the tests, conducted by the U.S. Naval Research Laboratory and Jensen Hughs, pitted a human operator controlling the robotic nozzle with a joystick against the FlameRanger fully automatic guidance of the same robotic nozzle. The human operator extinguished the test fire in 20 seconds with approximately 380 liters of water, whereas the FlameRanger extinguished the same sized test fire fully autonomously in only 15 seconds and used only approximately 250 liters of water. In short, the automatic system worked faster and more efficiently than the human operator.”

A fully presentation with detailed explanation of how the system works can be viewed in the following video:

For most automatic system applications, Unifire recommends the FlameRanger system over systems that use thermal imaging cameras, such as Unifire’s HeatRanger system, because it has virtually no vulnerability to false alarms.

Automatic Fire Detection & Suppression Systems Combining FV300 IR Array Flame Detectors and Thermal Imaging Cameras

As discussed in more detail above, flame detectors have superior advantages in terms of very low false alarm rates and rapid detection of visible flames. The primary disadvantage for certain applications, however, is that they do not detect a heat buildup which can give an early warning of a possible problem before fire breaks out.

The best solution possible combines the benefits of both IR flame detectors and thermal imaging, and eliminates the disadvantages. To achieve this, Unifire recommends the FlameRanger system and the installation of a separate thermal imaging camera that provides an early warning to a human operator, who can review the situation and take manual remote control of the robotic nozzle (water or foam monitor) for human intervention.

This combined system eliminates the automatic function in the event of a false alarm by thermal imaging cameras, yet still provides the benefit of an early heat buildup detection by the thermal imaging cameras. At the same time, if flames ever to appear, they are rapidly detected by the IR flame detectors which in turn trigger the fully automatic response from the robotic nozzles with a high degree of accuracy to target the fire.

Automatic Fire Fighting Systems Using Video Analytics

Unifire is now in the early stages of researching and developing a fully automatic fire detection and suppression systems that will utilize video analytics for detecting flames, smoke and possibly other hazards, such as oil mist and/or reflection of flames.

Unifire anticipates that such systems will be highly sensitive, provide relatively precise location information of the fire/smoke’s source, and will offer an economical solution for applications in which video analytics detection are well suited.

Much like with thermal imaging cameras, however, a significant challenge to mitigate is overcoming or mitigating false alarms inherent in video analytics fire and smoke detection technologies.

Unifire is excited by the possibilities offered by video analytics detection methodologies, yet uncertain as to whether such systems can be practical given their proneness to false alarms.

Automatic Fire Fighting Systems Using Other Detection Technologies

Unifire is able to provide fully automatic fire suppression systems based on any alarm input data. This can include heat detectors, such as fibre optics, laser smoke detectors, gas detectors, or even a simple smoke detector.

To be effective, however, time of detection is crucial. In Unifire’s experience, flame detectors offer the most reliable and rapid fire detection available.

When flame detectors cannot be used, for some reason, then it is certainly possible to offer automatic systems that react to signals from virtually any detection device.

The more accurate the location data of the fire, the more effective the system will be to suppress it. When accurate information about the source of the fire or heat is not available, the system can still be programmed to react to any pre-defined. If a detector can provide a zone or specific location in which a fire or heat buildup is detected, Unifire’s system can react to that zone or area alone, and cover the entire area of that zone. The same is true for multiple zones, such as the HeatRanger system using multi-zones detected from the thermal imaging cameras.

The only requirement is that Unifire’s system receive a signal to commence suppression. The reaction of the robotic nozzles then is a matter of setting on site and taking into consideration the level of accuracy provided by the detectors.

CONCLUSION

Recycling and waste management plants can now source complete, off-the-shelf automatic fire detection and suppression systems that are tailored to their needs. These systems can include thermal imaging cameras and/or flame detectors and/or other detection technologies.

For more information and to discuss your needs and the best-fit solution for your application, contact Unifire AB of Sweden (Unifire.com).

Author: Roger Barrett James, Esq.